If you think metal products are just steel bars and sheets, think again. In 2026, metal product manufacturing is a lot more than that. It’s about smart technology, better designs, faster production, and even sustainability. Everything from the buildings we live in to the bridges we cross depends on high-quality metal products. And behind all this are the steel detailing companies, making sure that every piece of steel fits perfectly, keeping structures safe and strong.

Let’s take a closer look at the trends, technology, and growth in this industry, explained in simple words anyone can understand.

Why Metal Products Are More Important Than Ever?

Look around you—metal is everywhere. From your office building to your favorite shopping mall, even the machines in factories rely on strong, precise metal products.

In 2026, the demand for metal is higher than ever because:

- Cities are growing, so we need more buildings, roads, and bridges.

- Factories and industrial sites need durable materials.

- New technology makes it easier and cheaper to produce high-quality metal.

And that’s where Steel Detailing Companies come in. They make sure that every steel beam and rod is measured, designed, and fabricated perfectly. Without them, mistakes in construction could cost a lot of money and even compromise safety.

Top Trends in Metal Product Manufacturing

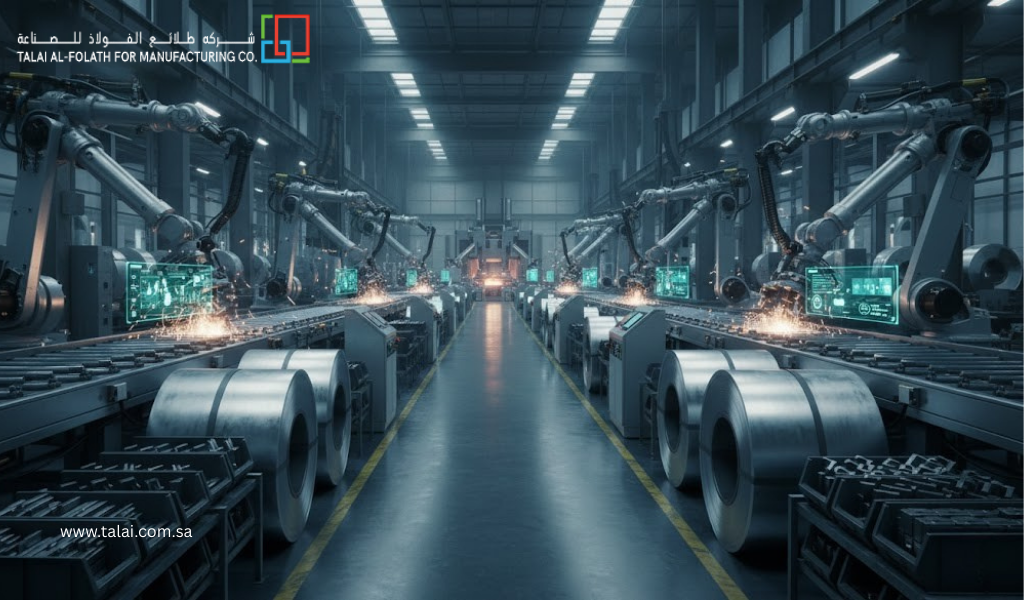

- Smart Factories and Automation

Modern factories aren’t like the noisy workshops of the past. Today, automation and smart machines do most of the heavy lifting. Robots cut, shape, and weld metal with high accuracy. Machines connected to the internet monitor production in real time, and AI helps predict and fix problems before they happen.

For steel detailing companies, this means faster, more accurate designs and less chance of errors on site.

- Sustainability Is Key

Everyone’s talking about going green, and metal manufacturing is no exception. Companies are:

Using recycled metals

Reducing energy consumption

Minimizing waste and emissions

Even steel detailing companies are part of this. They optimize designs so less steel is wasted, which is better for the planet and saves money.

- Custom Designs Are in Demand

Gone are the days when standard steel shapes were enough. Architects and engineers want unique designs for modern buildings and special industrial projects.

Steel detailing companies help make this possible by creating precise, customized plans that meet exact specifications. This ensures that construction goes smoothly and safely.

- Digital Tools Make Life Easier

Communication is easier than ever thanks to digital collaboration tools.

3D models and BIM software let everyone see the structure before it’s built.

Cloud platforms allow teams to share designs and updates in real time.

For steel detailing companies, this reduces mistakes and keeps everyone on the same page, making projects faster and smoother.

- Stronger, Lighter Materials

Metal isn’t just steel anymore. Manufacturers are using new alloys and composites that are:

Stronger

Lighter

More durable

This gives steel detailing companies more options to design structures that are safe, cost-effective, and modern-looking.

How Technology Is Driving Growth?

Technology is changing everything in metal manufacturing:

Robots and Automation: Machines handle repetitive work with precision and speed.

3D Printing: Complex metal parts can now be made faster and with less waste.

Advanced CAD and BIM Software: Helps steel detailing companies design structures that fit perfectly.

IoT Sensors: Track machine performance and prevent mistakes before they happen.

AI Analytics: Helps predict production problems, reduce delays, and save costs.

With these tools, manufacturers can deliver high-quality products faster, and steel detailing companies can ensure every project is safe and accurate.

Opportunities for Growth

2026 is full of chances for metal manufacturers:

Infrastructure Projects: Governments are building roads, bridges, and public buildings.

Private Construction: Homes, offices, and factories all need strong metal.

Global Market: Manufacturers can supply projects anywhere in the world.

Unique Designs: Architects want creative and innovative steel structures.

By embracing technology and focusing on quality, manufacturers and steel detailing companies can grow in this expanding market.

Why Steel Detailing Companies Matter?

You might wonder, what exactly do steel detailing companies do?

They are like the bridge between design and construction. Their work ensures that steel structures are:

Accurate and safe

Optimized to reduce waste

Delivered on time and cost-effective

Built without errors that could slow construction

In short, they save money, prevent problems, and make construction faster and safer.

Challenges Metal Manufacturers Face

It’s not all easy. Some challenges in 2026 include:

Rising material costs

Shortage of skilled workers

Strict environmental rules

Competition from global suppliers

To overcome these, manufacturers must invest in technology, focus on sustainability, and partner with skilled steel detailing companies.

Conclusion: Building the Future with Metal

Metal product manufacturing in 2026 isn’t just about making steel and metal parts—it’s about innovation, precision, and collaboration.

With technology, sustainability, and smart design, manufacturers can grow faster and deliver better products. And steel detailing companies are at the heart of it all, making sure every structure is safe, strong, and efficient.

If you’re in construction, architecture, or industry, working with reliable metal manufacturers and steel detailing companies isn’t just smart—it’s essential. The future of buildings, bridges, and infrastructure depends on it.

In 2026, metal is more than just a material. It’s the backbone of progress, shaped by technology, innovation, and careful planning.

FAQs About Metal Product Manufacturers and Steel Detailing Companies

What do metal product manufacturers do?

Metal product manufacturers create steel, aluminum, and other metal products used in buildings, bridges, factories, and machinery. They make sure the metal is strong, durable, and ready for construction or industrial use.

Why are steel detailing companies important?

Steel detailing companies make precise plans for steel structures. They ensure every beam, rod, and connection is accurate, saving time, money, and preventing mistakes during construction.

What are the latest trends in metal manufacturing?

In 2026, trends include smart factories, automation, sustainable practices, customized designs, and digital collaboration using 3D modeling and BIM software.

How is technology changing metal manufacturing?

Robotics, AI, IoT sensors, 3D printing, and advanced design software help manufacturers produce metal faster, reduce errors, and improve quality.

Can steel detailing companies help reduce construction costs?

Yes! By optimizing steel designs and reducing material waste, steel detailing companies save both time and money while ensuring safety and accuracy.